12

Basic Info.

| Model NO. | HDI PCB 000100 |

| Processing Technology | Electrolytic Foil |

| Base Material | Copper |

| Insulation Materials | Epoxy Resin |

| Transport Package | Vacuum Packaging |

| Origin | Shenzhen |

| HS Code | 8534001000 |

| Production Capacity | 30000sqm/Month |

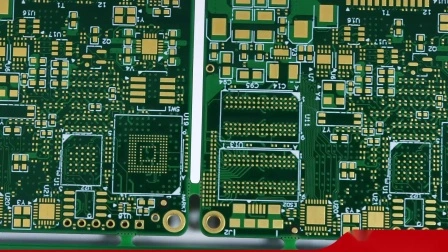

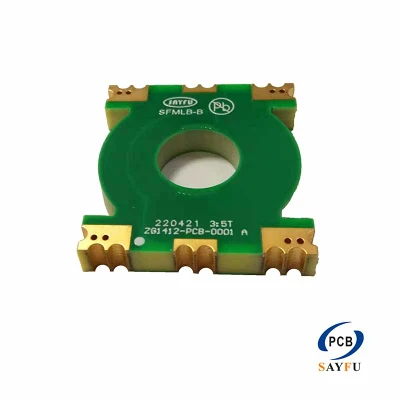

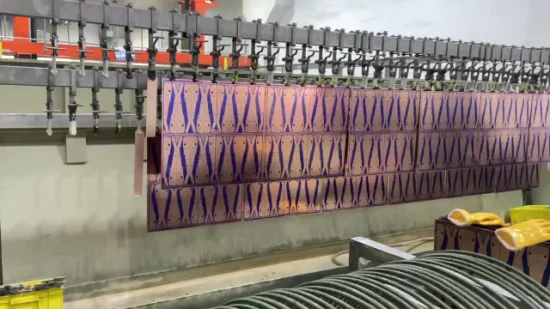

Product Description

Product Description

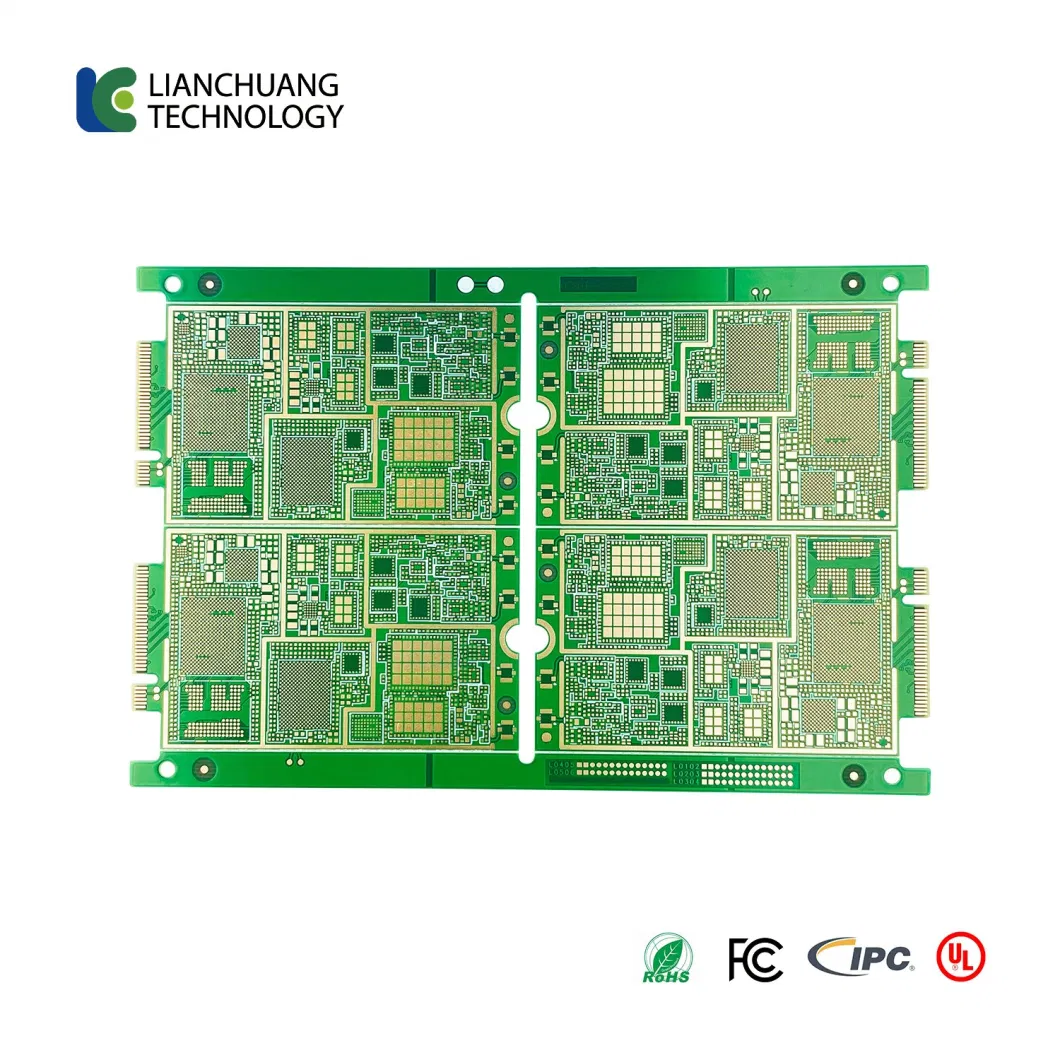

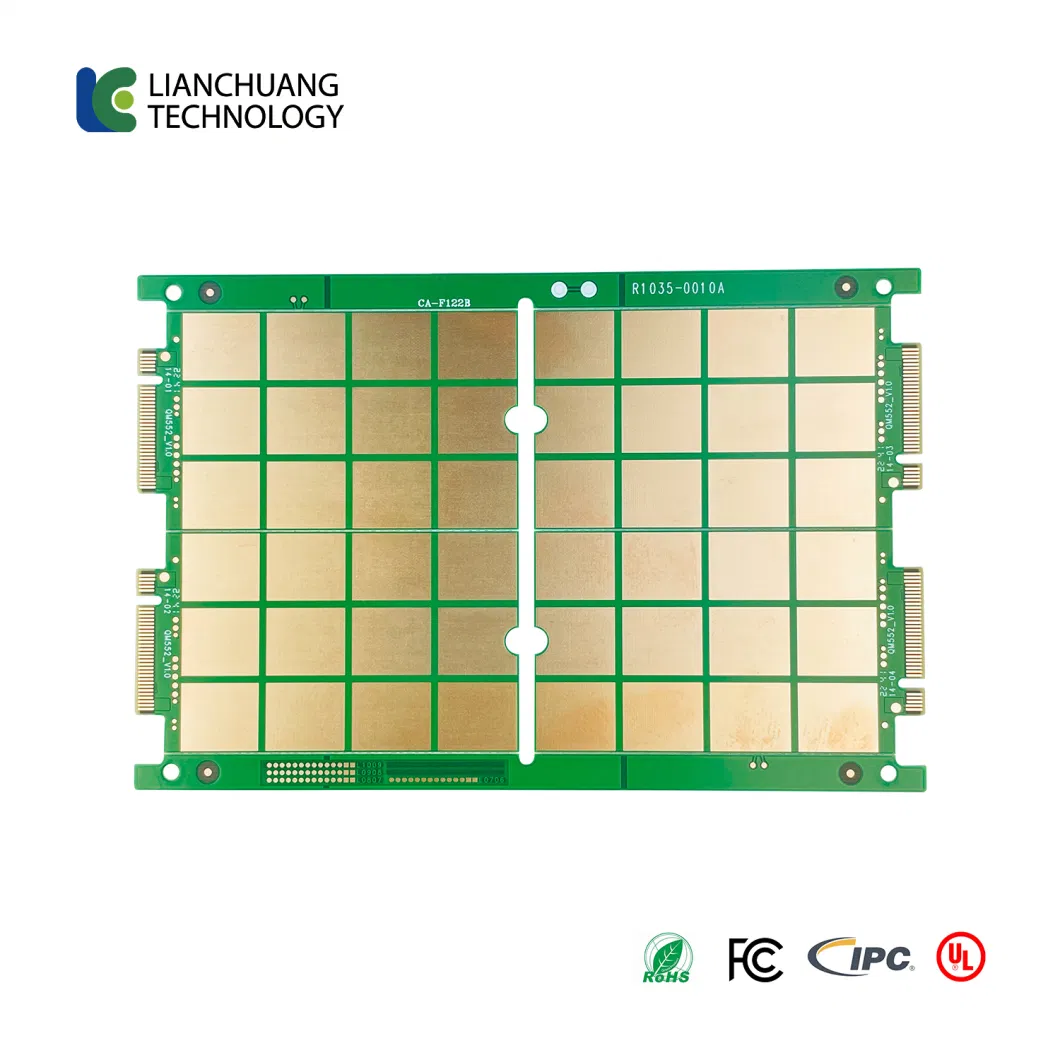

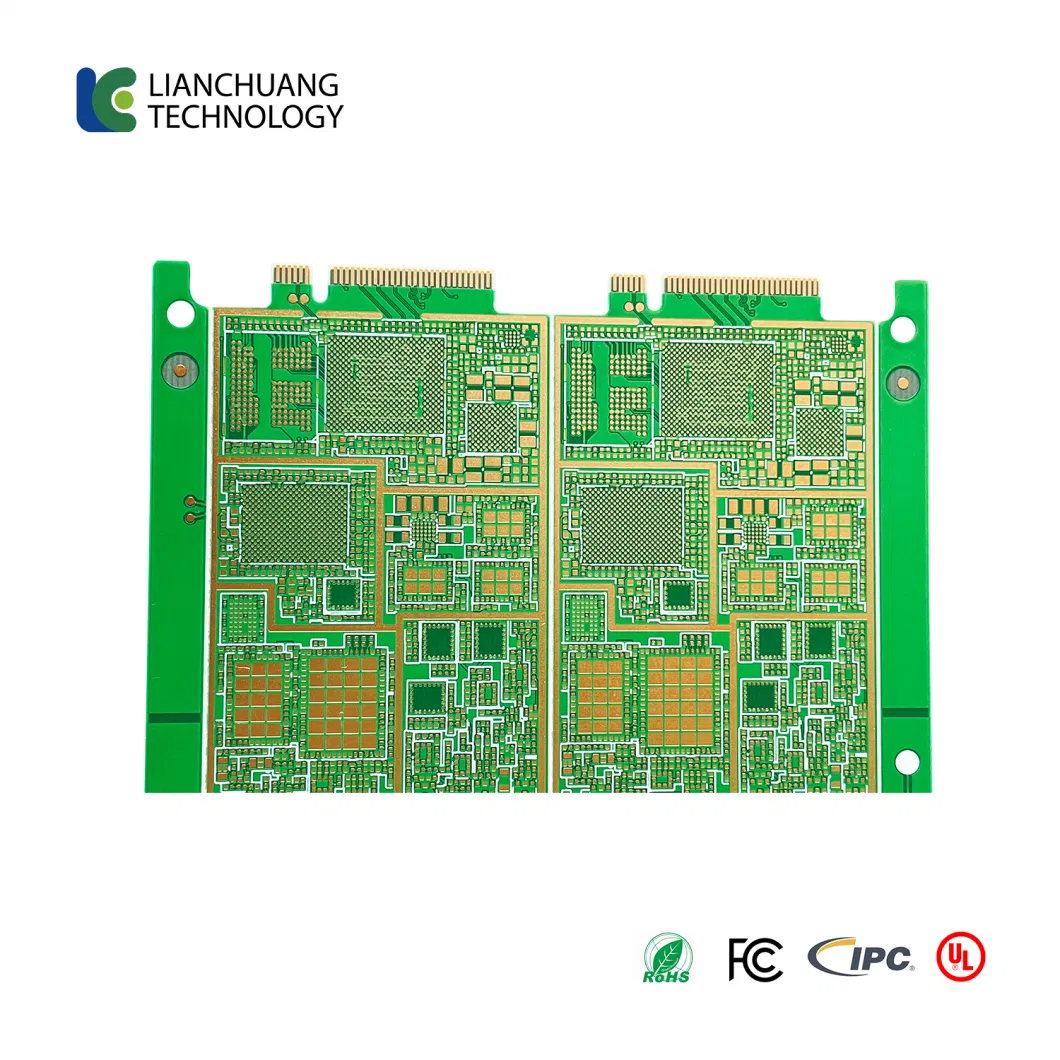

Detailed Photos

CAPABILITIES

Our Advantages

WHY CHOOSE LIANCHUANG TECHNOLOGY ?

Quick-Turn Production

Lianchuang Technology offers small volume production in 5-6 days and medium-to-large production in 2-3 weeks.

Make Logistics Easier

When you work with us, there is no need to deal with multiple suppliers, language barriers, customs headaches and shipping logistics. We do it all - and deliver to your designated port.

Cost Savings

With our global buying power combined with the capabilities of our overseas manufacturers, we're able to provide tremendous savings for our customers.

MATERIALS AVAILABLE

All the right materials for your next project.

RoHS CompliantTurn to Lianchuang Technology to manufacture RoHS-compliant PCBs. We typically use SYST,Nanya ,Rogers products, as well as other options right for your project.

Materials include:

- FR-4 Standard Multifunctional 130 Tg

- FR-4 High 170 Tg

- KB 6160C/6167GMD

- Hight CTI : Shengyi S1600 ; Normal: S1141,S1155,S1165(halogen free)

- HDI PCB Material : LDPP(IT-180A 1037&1086 Normal PP 106&1080)

- Wangling F4BK series

- High ZYC800X

- NAN-YA NPG-R/NPG-TL NP-180

- Rogers4350,4003

- ISOLA 410

- Hybrid laminating : Rogers/Taconic/Arlon/Nelco laminate with FR-4 material (including partial Ro4350B hybrid laminating with FR-4)

- Thermal Clad (including Aluminum Bonding)

- Others including Flex

- Immersion Tin (Sn)

- Immersion Sliver (Ag)

- Immersion Gold (Au)

- ENTEK/OSP (Organic Solder Preservative)

- Leaded

- Leadfree HAL

- Soft bondable gold

- High Tg/High performance FR-4 material

- Halogen-free solder mask

- Lead-free surface finishes

Contact Us for more information

TECHNOLOGY ROADMAP

| Item | RIGID | FLEX | RIGID-FLEX |

| Max Layer | 32L | 8L | 26L |

| Inner Layer Min Trace/Space | 3/3mil | 3/3mil | 3/3mil |

| Out Layer Min Trace/Space | 3/3mil | 3.5/4mil | 3.5/4mil |

| Inner Layer Max Copper | 8oz | 2oz | 8oz |

| Out Layer Max Copper | 8oz | 2oz | 2oz |

| Min Mechanical Drilling | 0.15mm | 0.15mm | 0.15mm |

| Min Laser Drilling | 2.5mil | 2.5mil | 2.5mil |

| Aspect Ratio(Mechanical Drilling) | 14:01 | 10:01 | 12:01 |

| Aspect Ratio(Laser Drilling) | 10:01 | / | 10:01 |

| Press Fit Hole Ttolerance | ±0.05mm | ±0.05mm | ±0.05mm |

| PTH Tolerance | ±0.075mm | ±0.075mm | ±0.075mm |

| NPTH Tolerance | ±0.05mm | ±0.05mm | ±0.05mm |

| Countersink Tolerance | ±0.15mm | ±0.15mm | ±0.15mm |

| Board Thickness | 0.2-8.0mm | 0.1-0.5mm | 0.2-8.0mm |

| Board Thickness Tolerance(<1.0mm) | ±0.1mm | ±0.05mm | ±0.1mm |

| Board Thickness Tolerance(≥1.0mm) | ±10% | / | ±10% |

| Impedance Tolerance | Single-Ended:±5Ω(≤50Ω),±7%(>50Ω) | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) |

| Differential:±5Ω(≤50Ω),±7%(>50Ω) | Differential:±5Ω(≤50Ω),±10%(>50Ω) | Differential:±5Ω(≤50Ω),±10%(>50Ω) | |

| Min Board Size | 10*10mm | 5*10mm | 10*10mm |

| Max Board Size | 22.5*30inch | 9*14inch | 22.5*30inch |

| Contour Tolerance | ±0.1mm | ±0.05mm | ±0.1mm |

| Min BGA | 7mil | 7mil | 7mil |

| Min SMT | 7*10mil | 7*10mil | 7*10mil |

| Surface Treatment | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating | ENIG,Gold Finger,Immersion Silver,Immersion Tin,HASL(LF),OSP,ENEPIG,Flash Gold;Hard gold plating |

| Solder Mask | Green,Black,Blue,Red,Matt Green | Green Solder Mask/Black PI/Yellow PI | Green,Black,Blue,Red,Matt Green |

| Min Solder Mask Clearance | 3mil | 3mil | 3mil |

| Min Solder Mask Dam | 3mil | 2mil | 3mil |

| Legend | White,Black,Red,Yellow | White,Black,Red,Yellow | White,Black,Red,Yellow |

| Min Legend Width/Height | 4/23mil | 4/23mil | 4/23mil |

| Strain Fillet Width | / | 1.5±0.5mm | 1.5±0.5mm |

| Bow & Twist | 0.30% | / | / |

FAQ

SUPERIOR PRODUCTION BACKED BY COMPETITIVE PRICING, QUALITY AND ON-TIME DELIVERY.

Take advantage of what our customers already know. Iianchuang has the experience and capability to fabricate the highest quality printed circuit boards. Plus, each project is backed by the service and confidentiality you demand.

we're able to offer you economies of scale from our global buying power - saving you money and giving us the ability to fulfill your more complex and larger PCB orders. Collectively, our facilities are UL94V-0, IATF16949:2016,IS014000:2015, and ISO9001:2015 certified.

In addition, With our fully staffed CAD CAM stations, we analyze every project for DFM compliance. By discovering and remedying potential manufacturing problems in the pre-fabrication stage, we able to provide the highest quality PCBs while meeting your deadlines.

Our quick turn prototypes are not just intended for testing and verification of designs. Every one of our boards meet IPC-A-600 F (Class 2) standard, whether it's prototype or production. To us, prototype also means 'per your spec' and delivered on time.

Lianchuang Technology focus on multilayer rigid pcb, High Density Interconnect pcb, Heavy copper board, High Frequency pcb/RF PCB & Ceramic PCB & Rogers PCB & Teflon PCB factory in China, now we can help customer do PCB assembly, Board assembly and DIP assembly services.

Around 280 full time staff with a capacity of 3ksqm per month, 10,000 square meter of factory

Kindly advise if any further info required and we will be happy to assist.

For price testing and try our service, you can send us your gerber file, we will quote to you right away.