PCBA Circuit Board Prototype PCB Assembly 94V0 Multilayer HDI Medical Equipment PCBA

Basic Info.

| Model NO. | JX-PCBA-01 |

| Base Material | Copper |

| Insulation Materials | Organic Resin |

| Model | Jx-PCBA |

| Brand | OEM |

| Certificate | ISO9001/ISO14001/CE/RoHS |

| Maximum Board Size | 640mm*1100mm |

| Surface Finishing | HASL\OSP\Immersion Gold |

| Solder Mask Color | Blue, Green, Red, Black, White., etc |

| Product Application | Consumer Electronics/Home Appliances/Medical Equip |

| PCB Silkscreen Color | Black, White, Yellow |

| PCBA Packaging | Static Packaging, Shockproof Packaging, Anti-Drop |

| PCBA Testing Service | AOI, ICT, X-ray, Flying Probe Test |

| Raw Material | FR4/Cem-1/Cem-3/FR1/Aluminum |

| Maximum Plate Thickness Aperture Ratio | 30:1 |

| Layer | 1-32 Layers |

| Board Thickness | 0.2mm-7.0mm |

| Service | One-Stop Turnkey |

| Minimum Mechanical Drilling Aperture | 6mil |

| Product Type | Custom HDI PCBA |

| Transport Package | Carton Box |

| Specification | 200 PCS/CTN |

| Trademark | Customer′s brand |

| Origin | China |

| HS Code | 8517799000 |

| Production Capacity | 10000PCS |

Product Description

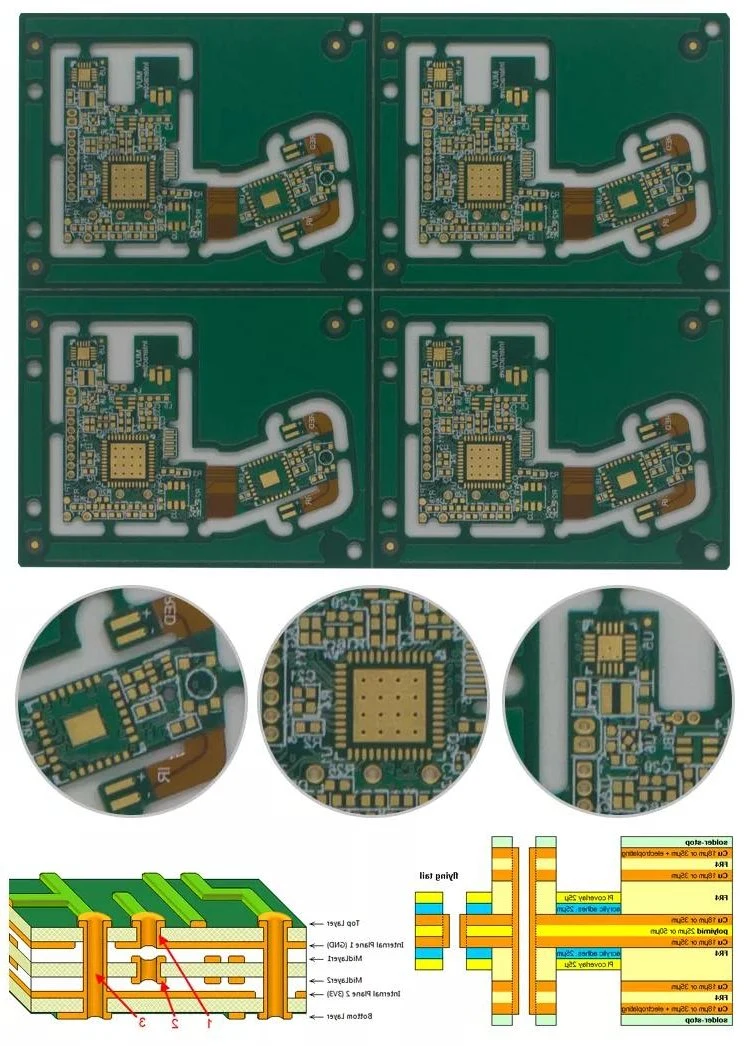

PCBA Circuit Board Prototype PCB Assembly 94V0 Multilayer HDI Medical Equipment PCBAProduct Description

| Specification: | |||||

| PCB layers: | 1-24layers | ||||

| PCB materials: | CEM1, CEM3, Rogers, FR-4, High Tg FR-4, Aluminum Base, Halogen Free | ||||

| PCB max. board size: | 620*1100mm | ||||

| PCB certificate: | RoHS Directive-Compliant | ||||

| PCB Thickness: | 1.6 ±0.1mm | ||||

| Out Layer Copper Thickness: | 0.5-5oz | ||||

| Inner Layer Copper Thickness: | 0.5-4oz | ||||

| PCB max. board thickness: | 6.0mm | ||||

| Minimum Hole Size: | 0.20mm | ||||

| Minimum Line Width/Space: | 3/3mil | ||||

| Min. S/M Pitch: | 0.1mm(4mil) | ||||

| Plate Thickness and Aperture Ratio : | 30:1 | ||||

| Minimum Hole Copper: | 20µm | ||||

| Hole Dia. Tolerance(PTH): | ±0.075mm(3mil) | ||||

| Hole dia. Tolerance(NPTH): | ±0.05mm (2mil) | ||||

| Hole Position Deviation: | ±0.05mm (2mil) | ||||

| Outline Tolerance: | ±0.05mm (2mil) | ||||

| PCB solder mask: | Black, white, yellow | ||||

| PCB surface finished: | HASL Leadfree,Immersion ENIG,Chem Tin,Flash Gold,OSP,Gold finger,Peelable,Immersion Silver | ||||

| Legend: | White | ||||

| E-test: | 100% AOI, X-ray, Flying probe test. | ||||

| Outline: | Rout and Score/V-cut | ||||

| Inspection Standard: | IPC-A-610CCLASSII | ||||

| Certificates: | UL (E503048),ISO9001/ISO14001/IATF16949 | ||||

| Outgoing Reports: | Final Inspection, E-test, Solderability Test, Micro Section and More | ||||

| PCB Assembly OEM Service | |||||||

| Electronic Components Material Purchasing | |||||||

| Bare PCB Fabrication | |||||||

| Cable, Wire-harness Assembly, Sheet Metal, Electrical Cabinet Assembly Service | |||||||

| PCB Assembly Service: SMT, BGA, DIP | |||||||

| PCBA test: AOI, In-Circuit Test (ICT), Functioal Test (FCT) | |||||||

| Conformal Coating Service | |||||||

| Prototyping and Mass Production |

| PCBA ODM service | |||||

| PCB Layout, PCBA Design According To Your Idea | |||||

| PCBA Copy/Clone | |||||

| Digital Circuit Design / Analog Circuit Design/ lRF Design /Embedded Software Design | |||||

| Firmware and Microcode Programming Windows Application (GUI) Programming/Windows Device Driver (WDM) Programming | |||||

| Embedded User Interface Design / lSystem Hardware Design |

Company Profile

Our factory located in Shenzhen, and have dust-free workshop which cover an area of over than 10000m², almost 550 employees, more than 30 production lines include SMT,DIP,automatic welding,aging test and assembly. We have equipments of over 50 SMT machines from Japan and Korea, automatic solder paste printing machines, solder paste inspection machine(SPI), 12 temperature zone reflow soldering machine, AOI detector, X-RAY detector, wave soldering machine, EM PCB dispenser, laser print machine etc., Different line configurations can meet requirements from small sample order to bulk shipment.

Our company has obtained ISO 9001 quality system certification and ISO 14001 system certification. With multi-testing procedures, our products carry out the quality system standard strictly. With end to end one-stop manufacturing solution, the company has become a benchmarking enterprise in the industry, and has been earning industry praises and good reputation from domestic and international customers depending on rigorous, techniques, good quality, fast delivery and excellent service.

ExhibitionsProduct ApplicationCertifications

Package & Shipment Our company is not only trying to give customers a good product but also pay attention to offering a complete and safe package. And here we prepare some personalized services for all the orders. Common packaging: PCB: Vacuum packaging with carton box PCBA:ESD packaging with carton box Shipping: 1.Confirming your shipping address is correct before delivery 2.Orders processed timely after the payment verification 3.Professional package. No worry about goods breakage. 4.Service transit time is upon different carrier, may vary particularly during holiday.FAQ

Q1.What is needed for quotation?

A: PCB : Quantity, Gerber file and Technic requirements(material, surface finish treatment, copper thickness, board thickness )

PCBA: PCB information, BOM, (Testing documents)

Q2. What file formats do you accept for production?

A: Gerber file: CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

Q3. Are my files safe?

A: Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process.All documents from customers are never shared with any third parties.

Q4. MOQ?

A: There is no MOQ. We are able to handle Small as well as large volume production with flexibility.

Q5.Shipping cost?

A: The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need usto quote you the shipping cost.

Q6. Do you accept process materials supplied by clients?

A Yes, we can provide component source, and we also accept component from client.